TITANIUM ANODIZE: FUNCTIONAL

Philosophy

Titanium Finishing Company started developing proprietary processes for functional anodizing in 1970 as an answer to galling issues in installing titanium fasteners into aircraft skins. It was found that anodizing titanium prevented this issue in metal-to-metal contact applications, and its use has spun off into various markets including, but not limited to medical, subsea and other aerospace operations.

Process

Functional titanium anodize is achieved by varying the mass of the oxide layer that naturally occurs on the titanium base metal beyond the initial rainbow of colors produced. Titanium Finishing Company can anodize pure titanium and its alloys in a range of thicknesses and colors to meet a variety of end user requirements and specifications. Each of the processes can be selectively masked for coverage, depending on individual needs.

- Tifin 400, “Fluffy Oxide” – Color is brown or gray, depending on the alloy. Thickness is measured at 0.0003 to 0.0005” growth.

- Tifin 200, “Lusterless Gray” – Color is a matte gray. This process creates no dimensional change and thus minimizes the need for masking of threaded holes and dowels. Also known as “Type 2” anodize.

- Tifin 200, Type IV – Same as above, post-treated with PTFE (Teflon) Impregnation for added lubricity.

- Tifin 300, Optical Gray for low emissivity – Color is a dark, charcoal gray. Thickness is measured at 0.0002 to 0.0004” growth.

Specifications

TFC operates under its proprietary process parameters and closely monitors the composition of its baths and use of voltages to create smooth, uniform anodize on titanium. In addition to the specifications listed below, Titanium Finishing Company anodizes in accordance with over twenty customer-written designations, each with their own parameters and uses in mind.

- AMS2488, Type II or “Type 2 Anodize”

- AMS2487

Features

- Prevents Fretting & Galling

- Prevents High Temperature Oxidation & Chloride Stress Corrosion

- Improves Emissivity Properties

- Increases Lubricity

- Non-toxic & Biocompatible

- Repeatability

- Stable, Unfading Tones

- Suitable Base for Paints, Adhesives & Lubricants

Available on All Titanium Alloys

Typical Applications

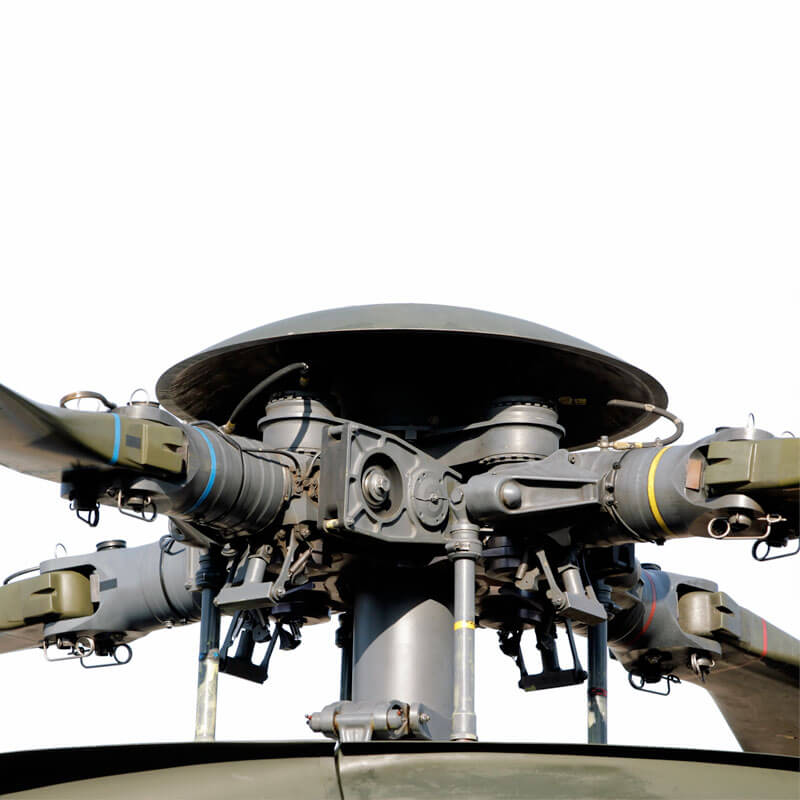

- Aerospace & Aviation

- Automotive & Racing

- Consumer Products

- Connectors

- Dental Implants & Devices

- Fasteners & Nuts

- Firearms & Sporting Goods

- Gears Hinges & Joints

- Machinery Components

- Medical Implants & Devices

- Military & Naval

- Optics Oil & Gas

- Orthopedics

- Pumps & Valves

- Subsea

- Threaded Surfaces

TITANIUM ANODIZING