SOLID FILM LUBRICANTS

Philosophy

Solid film lubricants, also known in the industry as “dry film lubes”, were introduced at TFC to be used as a post-treatment, sacrificial coating on aerospace fasteners in the 1970’s. Specific lubricants were chosen per various customer requests to best fit their needs. No two problems were exactly alike, ranging from the need for additional lubricity, difficult operating temperatures and wear resistance issues, to high load pressures, chemical exposure and lack of access for maintenance of traditional wet lubricants. TFC turned to Everlube Products for their expertise and high quality lubricants, and continues to apply their time-tested products today.

Process

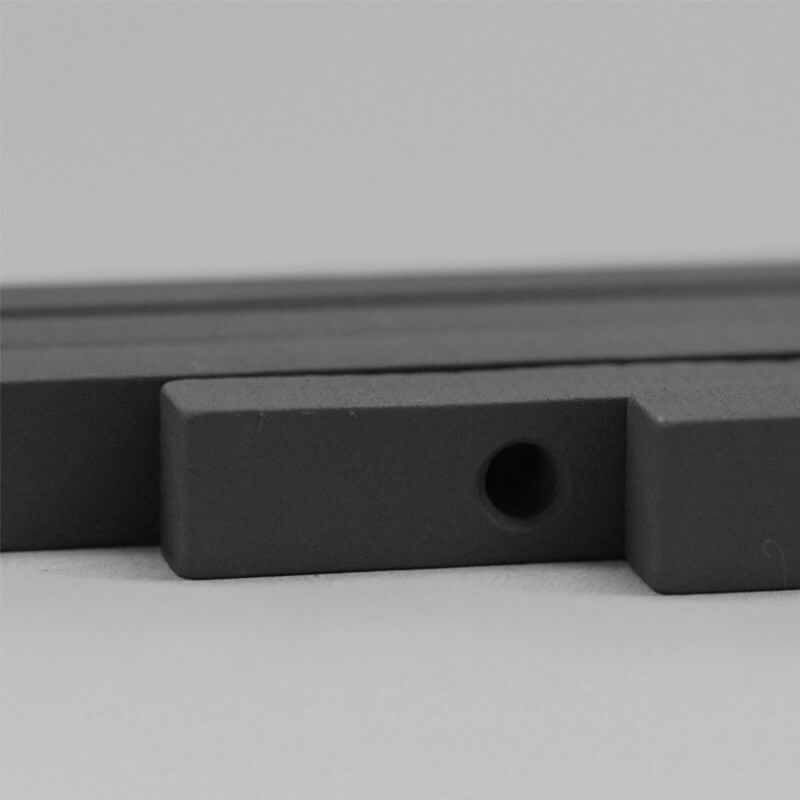

TFC maintains both automated and manual facilities for the application of solid film lubricants, with various sized spray booths, fixturing and curing ovens to accommodate a variety of shapes and sizes. The coatings can be applied to the entire part, or masked for selective surface treatment where applicable.

TFC offers solid film lubricants as a stand-alone process, or as a value-added post-treatment to both TFC’s titanium anodize and hard anodize of aluminum. There are a wide variety of solid film lubricants available on the market to fit your custom needs, so please see the Technical Data Sheets provided for specific product solutions, benefits and directive compliances. If you are interested in a product that you do not see listed in the specifications or technical data sheets, feel free to ask us if we would be interested in researching and applying a new product.

Specifications

TFC provides solid film lubricant coatings to aerospace, industrial, and the following military specifications:

- MIL-L-46010, Type I or Type II

- MIL-L-81329A

- Customer drawn specifications and parameters

Features

- Increased Lubricity

- Protection from Corrosion & Chemicals

- Increased Wear Resistance

- Sacrificial Coating

- Broad range of operating temperatures & environments available

- High Load Capacity

- No maintenance required, unlike greases & oils

Typical Applications

- Equipment with heavy loads prone to seizing

- Moving parts such as gears, ball joints, bearings, rollers, fasteners, and slides

- Dusty or dirty environments that would otherwise contaminate wet lubricants

- Harsh environments where contamination or degradation may occur by contact with chemicals, solvents or fuels

- High temperature applications

- Protection from galvanic corrosion in dissimilar metals

- Inaccessible parts where maintenance of lubrication is difficult or impossible due to location

Substrates

- Virtually all metals

- TFC Anodized Titanium Products

- TFC Hard Anodized Aluminum Products

SOLID FILM LUBRICANTS